-

Design Solutions

Our Engineers can assist you on Design projects small and large using the latest in 3D CAD simulation software.

-

Laser and Punching

Micron uses the latest in fully automated Laser and Form cutting technology, ensuring the best possible results.

-

CNC Bending

Micron uses the latest in CNC press brake technology, allowing us to work to the highest tolerances.

-

Fabrication

Highly skilled MIG, TIG and Spot Welding. From one off prototypes to OEM production runs.

-

Powder Coating

High quality powder coating in house so we can take extra care with your products.

-

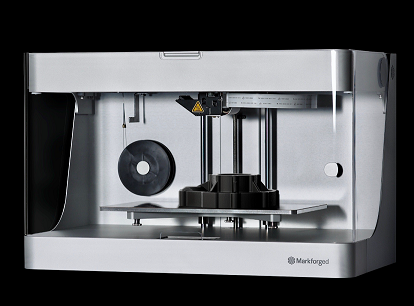

3D Printing

3D Print usable parts in Carbon Fiber, Kevlar, Fiberglass and Nylon

Virtual Prototyping VPSS

Micron Manufacturing uses the latest Virtual Prototyping Simulation software to verify your project in 3D, ensuring your products are correct first time every time.

Virtual prototype Simulation Software uses a comprehensive database of data and parameters from the factories actual machines, tools and materials in generating 3D CAD models.

Factory Monitoring and Shop Management for the 21st Century

Previously, no tool was available to monitor your factory in real time. As your business grows, it becomes more and more difficult to have accurate information about your shop operation.

With implementing a Real Time solution, V-Factory. Monitoring your factory in real time becomes a reality. Because it is built on web-based technologies, you can access it anywhere, at any time, in your common web browser.

Machines are visible in the main screen with status indicators and alarms: A green machine indicates that it is running. A yellow machine icon indicates standby mode. A red machine icon indicates alarm mode.

- Increased machine utilisation (up to 85%)

- Lowering costs per part and reduced scrap

- Drastic lead-time reduction

- Traceability of products

- Moved set-up off the shop floor

- Managing machine productivity

- Gaining shop floor control (ownership of information)

- Retrieving & utilizing data

- Significant reductions in direct labor costs

Efficient Manufacturing

Micron Manufacturing uses the latest manufacturing techniques and technology to bring your ideas to life at standards that will exceed your expectations. How do we do it?

-

Industry knowledge and experience

Micron Manufacturing works with industry leaders from commercial kitchens to rail to mining. This experience gives us the confidence to take on new challenges no matter how big or small.

-

Quoting and Tracking

Micron Manufacturing uses the most advanced Enterprise Resource Planning software available to give our manufacturing process full accountability and control.

When a new project enquirey is received, quotes are quickly and accurately generated, drawing on our vast experience.

Orders are electronically scheduled and issued with barcodes which are tracked at each work station through each stage of the projects development. This allows us to know exactly which stage the project is at, at all times.

This system also gives us the ability to monitor and fast track customer orders in response to customer requirements.

-

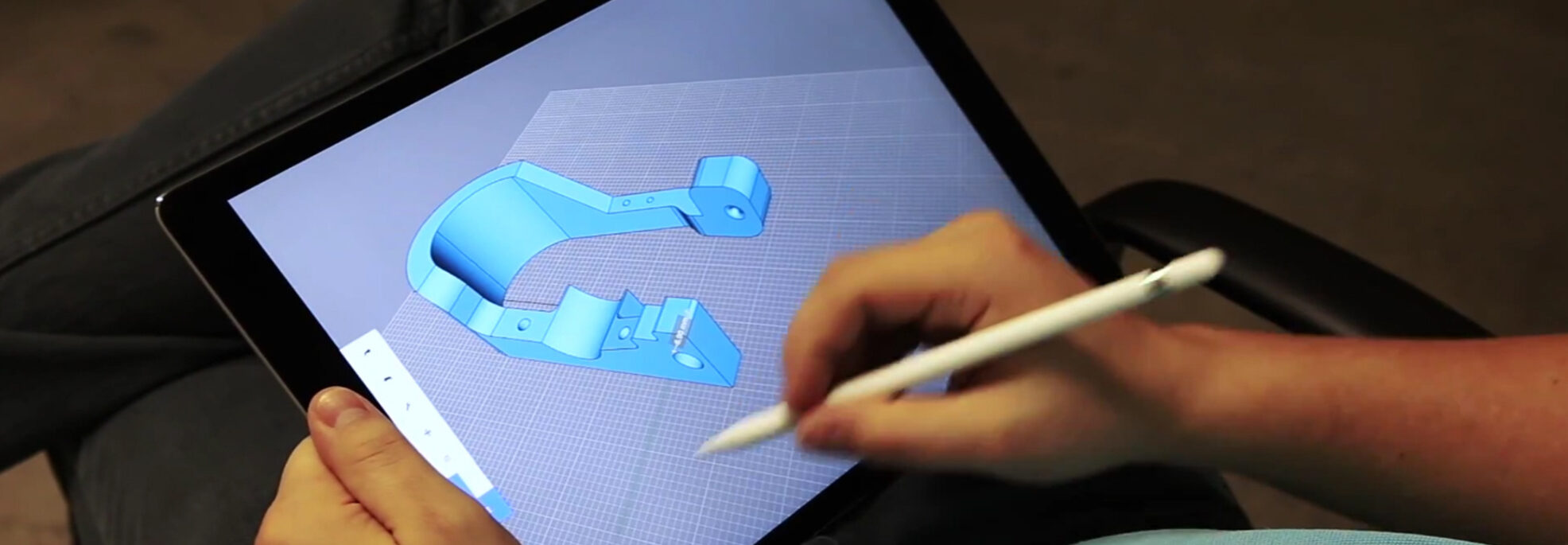

Design and Engineering

Micron Manufacturing has a team of University qualified Engineers who can bring your ideas to life using the latest in 3D CAD Virtual Prototype Simulation Software.

We can provide detailed working 3D renderings of your projects for verification prior to manufacturing. We also have the facilities to ensure products can actually be manufactured during the design process.

No products at Micron Manufacturing are released for production unless verified in 3D, leading to higher quality components and gaurenteed satisfaction for our clients.

To learn more about Design and Engineering click here.

-

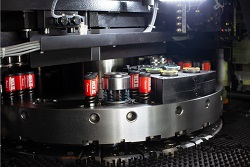

Laser Cutting and Punching

Micron Manufacturing uses a specially selected Amada Laser cutting system which is designed with the flexibilty for the high-mix, low volume production environment of the Australian sheet metal industry.

Our machines feature quick setup, easy material loading, high quality edge finish and synchronised rollers which allow for high throughput of scratch free stainless steel and aluminum parts.

Micron Manufacturing also takes advantage of the eco-friendly AC-Servo direct drive EM-series turret punch from Amada, allowing for high speed processing of perforated panels and formed parts.

To learn more about Laser and punch processing, click here.

-

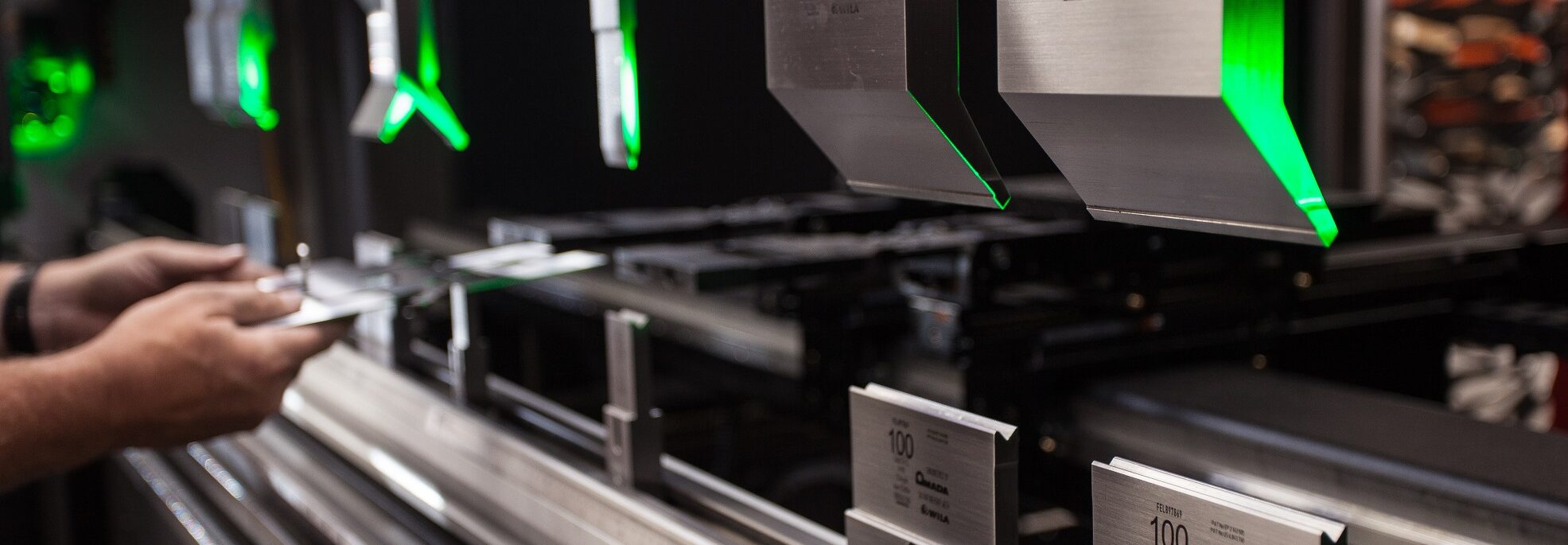

CNC Bending

Micron Manufacturing performs CNC bending across a wide range of materials using eco-friendly Amada Hybrid-Drive HDS press brakes.

The HDS is an extremely accurate, electric/hydraulic press brake that is engineered to deliver print-to-part processing and multi-stage bending while eliminating test pieces.

The systems super accurate ram is capable of repeatability to within tolerances of +- 0.001mm. The offline simulation and programming software allow for the generation of programs and setup data external to the

press brake.This translates into bending results with higher tolerances and quality as well as shorter lead times for our customers.

To learn more about bending, click here.

-

Post Processing

Micron Manufacturing offers a wide range of sheet metal post processing solutions including nut inserting, riveting and tapping.

-

Welding

Micron Manufacturing offer the following welding services in a range of materials including aluminium, mild steel and stainless steel:

• MIG Welding

• TIG Welding

• Spot Welding

• Stud WeldingAll parts are dressed to a high standard with finishing processes applied to meet your specific requirements.

-

Finishing

We can offer a full range of finishing solutions from powder coating and galvanizing, to polishing.

-

Quality Control

Micron Manufacturing is certified by the international standard ISO9001:2015 through SAI Global.

-

Delivery

Micron can arrange or personally deliver finished components to all corners of the globe.

Industry Knowledge

Micron Manufacturing has the skill and capabilities to service all Industry sectors

-

Mining and Resources

-

Government Projects

-

Rail and Infrastructure

-

Custom Vehicle Fit-outs

-

Electrical Projects

-

Custom Enclosures and Assemblies

-

Stainless Steel and Aluminum

-

Retails Solutions

-

Architecture

-

Interior Architecture

Latest News